Take advantage of our free TRIAL offer :

Send us up to 10 of your RPDs

and we will polish them

absolutely

for free

All you do is pay for shipping each way.

Revolutionary

liquid free

electro polishing

for dental labs

and dental industry

Distributed in North America by 3DRPD

Free introductory offer

CONTACT-US

3DRPD® exclusive North American distributor to the dental industry

3DRPD® is proud to be the exclusive North American distributor of DLyte’s revolutionary® electro-polishing technology.

Headquartered in Montreal, Canada, and with operations in the United States and Canada, 3DRPD® is dedicated to staying ahead of the game providing superior 3D laser printed removable partial denture (RPD) products to its customers around the world.

BEFORE

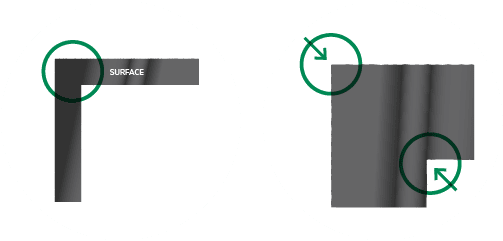

The process removes material only

from the peaks of roughness.

AFTER

The process not round edges and

can penetrate in all dead zones.

BEFORE

AFTER

45 minutes with dlyte 10d

BEFORE

Result after current Mechanical-Manual Polishing + Classical Electropolishing

AFTER

DLyte® Dental System

Unique patented polishing technology for RPDs

is now available to the North American dental market!

DryLyte’s® new patented technology provides the dental industry unequaled precision and quality grinding and polishing stainless steel and chromium cobalt appliances. Unique ion transport technology utilizes free solid bodies. Revolutionary dry electro-polishing that not uses any liquid as electrolyte.

From cast to mirror-finishing polishing in just one completely automated process.

The entire process is carried out using one machine significantly reducing waiting and preparation time. Process 9 pieces simultaneously. Optimal performance is achieved thanks to our high energy extracting process.

The polishing action reaches every corner of the piece, so it can process inner cavities which cannot be accessed mechanically.

Pieces can be processed without affecting the properties of resin bonded to the skeleton. Dielectric parts remain unaffected by the process.

Unlike mechanical processes, DLyte® does not round edges and can penetrate all dead zones. Along with the extraction performance this permits the creation of new designs which would not have been feasible until now.

The process achieves the highest polishing quality with minimal removal of material.

The fully automated process does not require any specialized labor. It also enables the mass production of pieces by removing the differences between them.

No need for abrasives which avoids a constant expenditure on consumables.

No environmentally harmful materials are used during the polishing process.