About us

3drpd

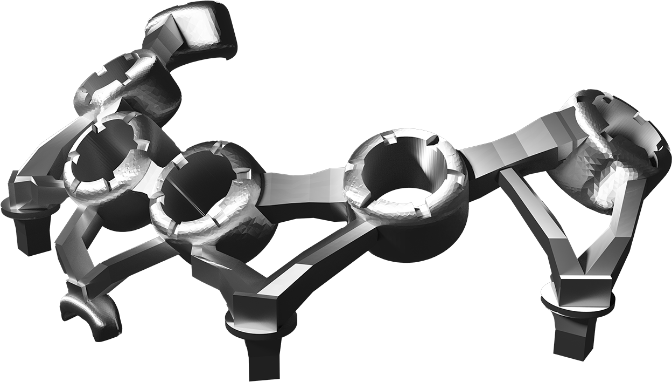

With over 15 years of expertise in producing cobalt-chromium RPDs, 3DRPD® recently expanded its offering with a new line of titanium frameworks, a material known for its light weight, biocompatibility, and exceptional durability — meeting the highest clinical demands.

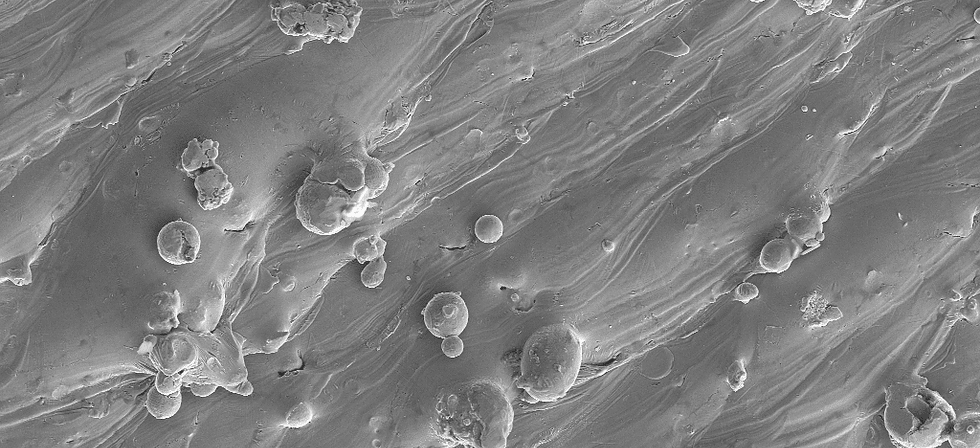

Production at 3DRPD® is driven by a science-based approach, with every step of the process — from metal powder selection to printing parameters and post-processing — grounded in peer-reviewed research and validated in in vitro studies.

The client experience is further enhanced by the 3DRPD® online portal, an intuitive communication platform that streamlines STL file submission, enables real-time case tracking, facilitates direct technical support, and provides a complete order history. This integrated system ensures greater efficiency, precision, and reliability for partner labs.